Installing Fixed Automation In Your Factory

What is Automation

Automation enables processes to happen on their own– i.e., promptly and without individual effort. In most cases, surveillance of processes can be automated, as well. Surveillance will commonly consist of summary data for crucial measurements, and can even be integrated with automated recommendation systems.

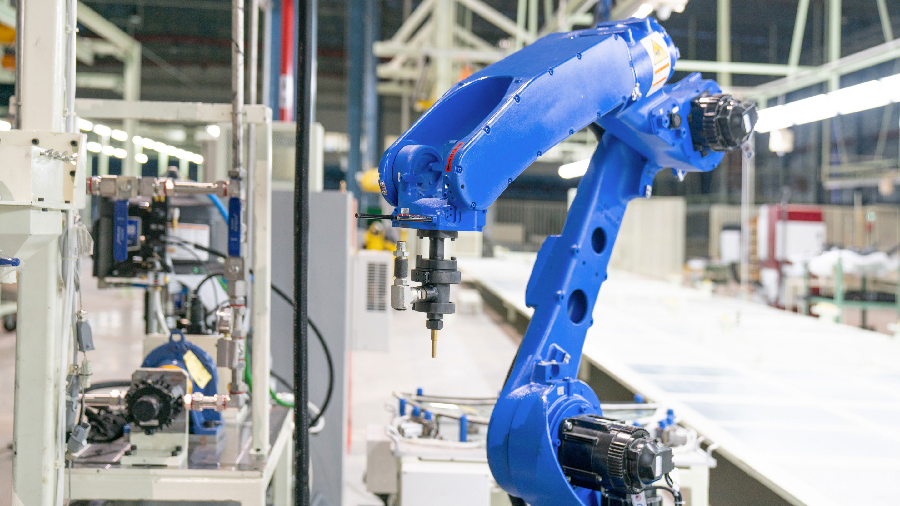

Automation will revolutionize a variety of crucial task functions throughout sectors such as robotics, cyber security, cordless applications and finance. Automation systems such as an liquid filling machine are already aiding various sectors traverse difficult problems in their operations tasks; the revolution is here.This is why it is important to understand automation, in particular its fixed variant, which is highly popular in production facilities around the world.

Implementing Automation in your Production Facility

Fixed Automation

Additionally known as Hard Automation, Fixed Automation includes the utilisation of specific-purpose equipment to automate a repetitive series of jobs, processing or assembly operations. Usually, the operational series is not complex, includes fundamental functionalities like rotational or plain direct motion, or an amalgamation of both.

The advantages of fixed automation are boosted speed of production, lowered cost of the unit, and the automation of the product handling process. If the automation repeats the same tasks with the same devices, it is Fixed Automation The most significant limitation, here, is that Hard Automation systems need to be replaced when new jobs require to be finished.

It is a system in which the sequence of processing (or assembly) operations is fixed by the equipment configuration. The operations in the series are generally basic. It is the integration and synchronisation of many such operations into one piece of equipment that makes the system complicated. The regular attributes of fixed automation are:

- High initial financial investment for custom-made– Engineered equipment;

- High manufacturing speeds; and

- Fairly stringent in fitting product modifications.

The financial justification for fixed automation is seen in products with really high demand rates and volumes. The high initial expense of the equipment can be spread out over a very large amount of units, thus making the unit expense appealing contrasted to alternate approaches of manufacturing. Examples of fixed automation consist of mechanized assembly and machining transfer lines.

Industrial Automation

Industrial automation involves making use of technology to handle the repetitive tasks, including those that are unsafe for human workers. Usual implementation examples consist of Numerically Regulated Equipment, Flexible Production Systems and Computer-Aided Manufacturing Industrial automation can enhance the precision of production and boost industry safety.

Computer-Aided Production

Computer-Aided Production (CAM) uses computer systems and equipments jointly to automate production. CAM is frequently integrated with Computer Aided Design (CAD) to enhance producing procedures. Some benefits of CAM include raised product and production consistency, raised production turnover, and enhanced component quality. CAD designs validated by engineer oversight is after that instantly recreated utilizing CAM.