Receive The Most Precise Results With Servo Motor Controls

When the term motor control is concerned, what it means is to use a stepper system or servo in the form of a “muscle” that can help lift and move a given load. Such motion controls act as very helpful tools as their operation is very precise concerning position, speed as well as torque control. Thus, for any sort of operation which requires accurate positioning of the products, precise synchronization of the various elements as well as fast start/stop the motion of the load, plc servo motor control is the ultimate choice for you.

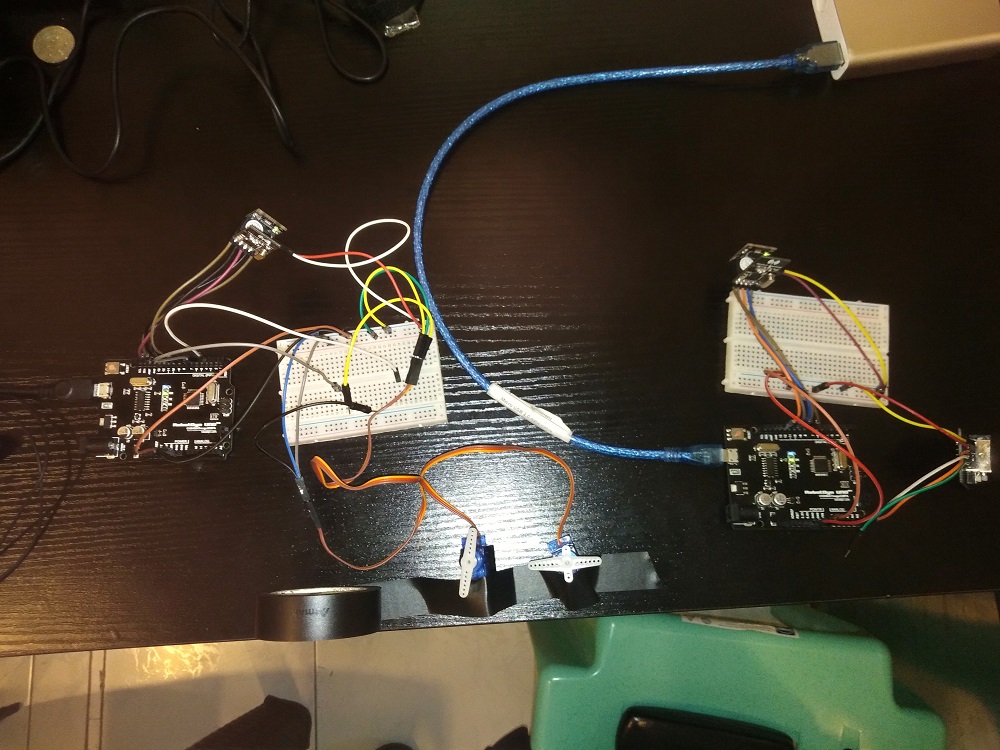

PLCs are an excellent industrial tool that aids in providing all the necessary signals that are required to operate and command all the servo as well as stepper systems in the most cost-effective and noise-free (digital) manner.

Thus, with the help of these controls, operating and moving loads become a lot more convenient and easy. These machines offer precise operations and perfect synchronization of the system concerning the different parts of the load.

How Does A PLC Motion Control Function?

Any typical motion control system comprises three very basic components: the controller, the drive, which is also termed as an amplifier; and of course the motor. The controller is responsible for handling the path planning or projector which in turn sends a low-voltage command signal to the diver or amplifier.

The driver is then responsible for applying the current and the voltage to the motor which is necessary for the desired motion to take place. Thus, the systematic and well-synchronized operation of the three different parts helps in obtaining the expected results.

What Makes PLC Motion Control A Convenient Option?

At times the motor or the load comes equipped with a feedback device that helps notify either of the control or the load about the very specific details of the real-time movement of the load or the shaft.

With the help of these feedback data that is received by the controller or drive, it can be very beneficial in improving the overall efficiency and accuracy of the motion. Moreover, it can also be very helpful in compensating for any sort of dynamic changes that may take place including the friction experience, the change in mass, or anything else.

Choosing PLC Motion Control Is A Smart Call

Considering the usage of PLC systems can be heavily beneficial in the long run. The capabilities that are offered by these systems are unmatched and are evolving years after years. The plc servo motor control can also be very easily automated which can be very helpful in ensuring precise and user-defined operations. Moreover, with the incorporation of software in the PLC technology, further discrete and hybrid controls application can be evolved.