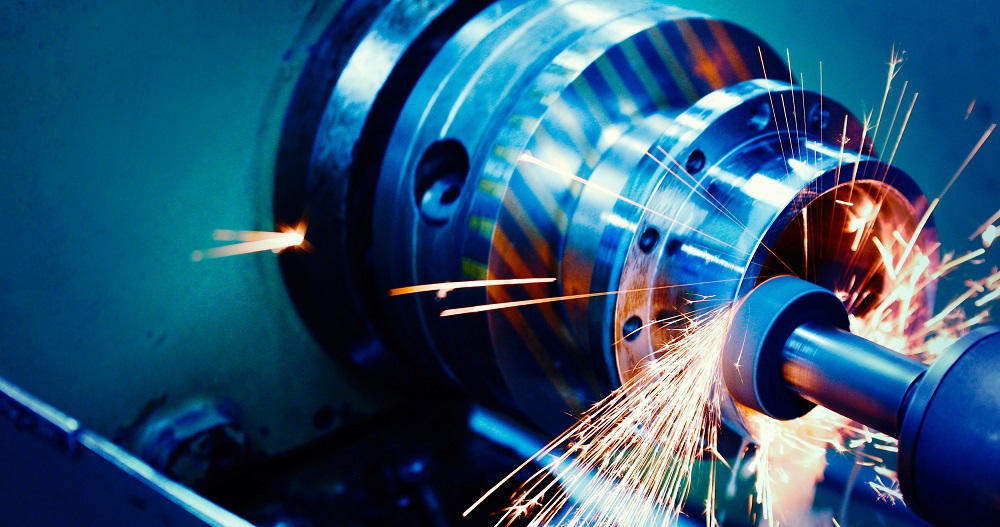

CNC Machining For Better Productivity

CNC (computer numerical control) machine operates the activities of other machines using numerical codes. CNC machining is a process in which CNC software is pre-programmed and set to monitor and operate the factory equipment and machinery. This advanced computer-monitored system conducts the activities of complex machinery and mainly accomplishes the tasks of grinding, cutting, mixing and the multiple steps procedures can be merged into a single step by this procedure.

Large CNC machine (เครื่อง CNC ขนาด ใหญ่, which is the term in Thai) are becoming increasingly popular in factories and industries as it cuts off manual labor, and substantially reduced the time required to execute the factory procedures. Also, it helps to get more accurate and precise results as you set the correct code for a task. This accuracy level can never be achieved manually.

How Does CNC Machining Works?

The CNC machining is activated and the codes are set up for each tool and machinery and then the machines start operating according to the predetermined codes.

The code generator in the CNC programming mostly generates flawless codes that would monitor the machines accurately. However, there can be a few chances of errors if the task is complicated. With the usage of part program inputs, the machines and tools are set with the numerical control system.

The task of inputting is done by punching cards. On the other hand, small keyboards are used for inputting codes into the large CNC machine. The codes are generated and fixed by professional programmers. The system and the coding system keep changing and the programmers keep updating codes to make the machines work more efficiently and accurately.

What Machines Are Operated Using A CNC Machine?

CNC programming is capable of operating a variety of factory tools including many complex pieces of machinery. What are these machines? Let us know about the machines that are monitored by a large CNC machine.

- CNC mills

- Lathes

- Plasma cutters

- Electric discharge machines

- Water jet cutters

- Turret punchers

- Embroidery machines

- Foam cutters

- Laser cutters

- Cylindrical grinders

- Glass cutters

- 3D printers

- Wood routers

- Wire-bending machines

What Are The Benefits?

CNC programming is extremely useful in modern times. Let us know why.

- It minimizes the time required for the manufacturing process increasing productivity.

- A greater accuracy level is achieved using CNC machines.

- It is a cost-effective procedure in large-scale productions.

Install a CNC machine in your factory today by taking assistance from trusted companies and expert programmers.